Roller Shell Manufacturer for Pellet Mill |

Hayne is a professional roller shell manufacturer for pellet mills, supplying helical roller shells, straight groove roller shells and special heat treated roller shells for poultry feed, cattle feed, aquaculture and biomass pellet production.

With over 10 years of export experience, Hayne provides OEM roller shells compatible with CPM, Andritz, Famsun and other major pellet mill brands.

Hayne manufacture top-quality Roller shell with Yearly Capacity 250000 pcs to different Industry, including Feed industry and Wood Industry. Our roller shells are trusted by leading feed groups and pellet producers worldwide.

Customized roller shell according to different request

Hayne custom-made roller shell according to client's special request

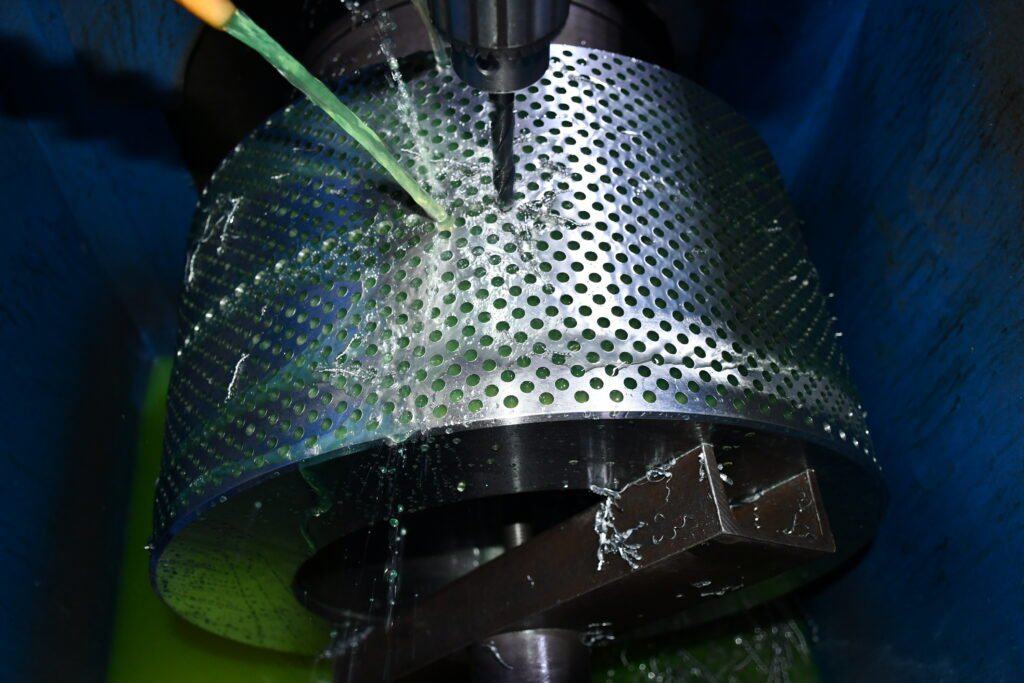

Durable pellet mill Roller shell come from advanced equipment and processes

Hayne owns fully automatic corrugated and dimpled processing machine and the largest heat treatment device for roller shell in China. From raw material monitoring to finished product delivery, every step of the process is meticulously controlled to ensure the highest quality and precision in our products.

Advanced Equipments And Processing

- FULL AUTOMATIC PROCESSING MACHINE---We use full automatic equipments to process corrugated and dimpled roller shell, ensure the precise size and smooth of the hole

- HEAT TREATMENT------ The largest heat treatment furnace of the world to meet mass roller shell processing and make sure delivery in time Full-automatic vacuum heat treatment furnace combined with advanced quenching processing of ring die to make sure the hardness to HRC52-55

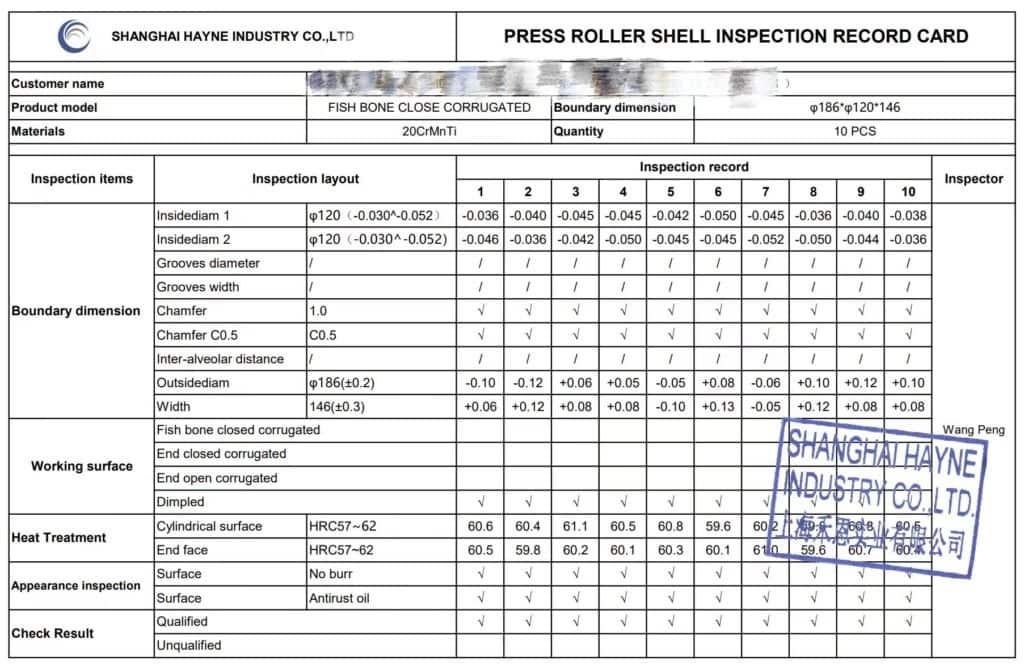

Professional Testing For Guaranteed Quality

Hayne Provide Inspection report for each die out of factory

Finshed Products

Hardness Check

Inspection report

How To Choose Different Type Roller Shell ?

CONTACT US

Are You Interested in Pellet Mill maintenance Guide? Contact Us!

Have A Questions ?

Whatsapp:+8618964879269

Monday - Friday

08.00 am - 07.00 pm/ Sunday (Closed)