In my past work, I’ve noticed that many customers pay a lot of attention to the ring die specifications, but often overlook the importance of matching the roller shell. For example, I’ve seen fine-hole aquatic feed dies being used with wide-tooth, high-pitch roller shells……

As one of the key wear parts of a pellet mill, the roller shell plays a critical role. Some customers have asked me how choosing the right roller shell can significantly improve pellet quality, reduce equipment wear, and increase overall efficiency.

As we know, the pellet mill roller shells have various types,with so many types of roller shells available, what’s the actual difference between them? And more importantly — how to choose the right one? Please keep reading to learn more about the types of roller shells, their features, and how to choose the most suitable one to optimize your pellet production.

📌 Table of Contents

- What Is a Pellet Mill Roller Shell?

- What Are the Common Types of Pellet Mill Roller Shells?

- How to Choose Roller Shells Based on Material Type?

- Is Choosing the Roller Shell Type Enough?

What Is a Pellet Mill Roller Shell?

A roller shell is one of the key components and spare parts of a pellet mill. It is used together with the die and presses raw materials into the die holes to form pellets. When the roller shell wears out, it is essential to choose the right one based on your materials and production needs.

The roller shell has patterns on its surface to make it grip better and turn smoothly with the die, without slipping. So roller shell directly impacts pellet quality, machine wear, and overall production efficiency. If we can select the right type, we can ensure consistent pellet production and reduce maintenance costs.

What Are the Common Types of Pellet Mill Roller Shells?

We can find several types of roller shells to meet different production requirements. Each type has unique features that make it suitable for specific materials and pelletizing processes.

Common roller shell types include dimpled, end-open corrugated, end-closed corrugated, inclined corrugated, fishbone, and curved corrugated designs and so on. Let’s understand these types to help you optimize your production process.

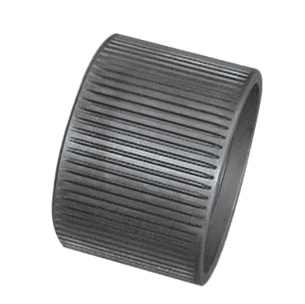

Dimpled (Honeycomb) Roller Shell

What it is: Small round dimples on the surface to increase grip.

What it’s for: Biomass, wood, or feed with medium fiber like grass powder or bran.

Why use it:

– Reduces slippage

– Makes die wear more even

– Produces tighter, more uniform pellets

Keep in mind: Not ideal for high-fiber materials like alfalfa or straw.

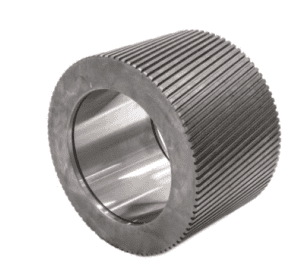

End-Open Corrugated Roller Shell

What it is: Grooved with open ends — no sealed edges.

What it’s for: Fibrous materials like livestock feed, ruminant feed, or wood pellets.

Why use it:

– Strong grip for hard-to-press materials

– Reduces die blockage, improves feeding

Keep in mind: May cause uneven die edge wear, requires regular checks.

End-Closed Corrugated Roller Shell

What it is: Grooved with closed- ends to prevent leakage.

What it’s for: Aquatic and poultry feed pellets.

Why use it:

– Closed ends prevent material leakage

– Builds more pressure, improves pellet shaping

– Increases output

Keep in mind: Needs regular cleaning to avoid buildup at ends.

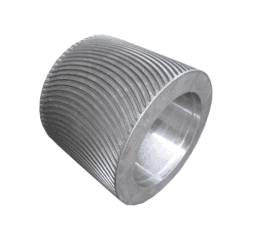

Inclined (Helical) Corrugated Roller Shell

What it is: Angled grooves for smoother guidance.

What it’s for:

– High-fiber cattle and sheep feed

– Biomass fuel pellets

– Large-diameter animal feed

Why use it:

– Moves material forward

– Reduces blockage, improves output

Keep in mind: Wears faster, uses more energy, not suitable for powdery materials.

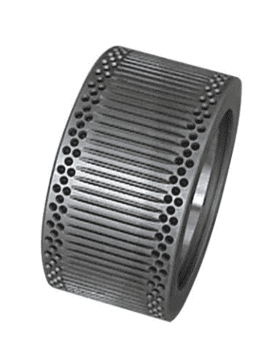

Fish Bone Corrugated Roller Shell

What it is: Fishbone-shaped grooves.

What it’s for:

– Various feed types

– Wood chips

– Pharmaceutical pellets

Why use it:

– Versatile

– Reduces slippage

Keep in mind: Slightly weaker grip for high-fiber materials.

Curved Corrugated Roller Shell

What it is: Curved grooves for smooth compression.

What it’s for:

– Wood chips

– Straw

– High-density materials

Why use it:

– Reduces breakage

– Maintains stable density

Keep in mind: Not good for sticky materials — may cause buildup.

Corrugated and Dimpled Roller Shell

What it is: Combination of grooves and dimples.

What it’s for:

– Wet or sticky feeds

– Grass-based materials

– Wood chips

Why use it:

– Combines grip and smooth feeding

– Reduces slippage on moist materials

Keep in mind: Not ideal for very fibrous materials like straw.

The above are the common types of roller shells we usually see. We’ve summarized them in the following table for easier reference

✅ Roller Shell Type Comparison Table

| Roller Shell Type | Surface Features | Best For | Advantages | Disadvantages |

| Dimpled (Honeycomb) | Small dimples for grip | Medium-fiber feed, biomass | Reduces slippage; even die wear | Not for high-fiber material |

| End-Open Corrugated | Straight grooves, open ends | High-fiber, rough materials | Strong grip; less blockage | Uneven die wear on edges |

| End-Closed Corrugated | Straight grooves, sealed ends | Aquatic & poultry feed | No leakage; better shaping; even length | Material buildup at ends |

| Inclined (Helical) Corrugated | Angled grooves | High-fiber, coarse biomass | Good flow; higher output | Higher wear & energy use |

| Fish Bone Corrugated | Fishbone-shaped grooves | Multi-purpose | Versatile; stable feeding | Weaker grip on high-fiber |

| Curved Corrugated | Curved grooves | Hard, dense materials | Less breakage; consistent density | Not for sticky materials |

| Corrugated + Dimpled | Grooves + dimples | Sticky/moist materials | Better grip; reduces slippage | Less effective for very high-fiber feeds |

How to Choose Roller Shells Based on Material Type?

1. Medium-Fiber Feed (e.g. grass powder, bran)

Recommended: Dimpled (Honeycomb) Roller Shell

Why: The small dimples add friction to prevent slippage without being too aggressive on the die.

Bonus: Helps keep the die wear even and pellets consistent.

Avoid: For very fibrous or coarse materials — grip may not be strong enough.

2. High-Fiber, Rough, or Fluffy Materials (e.g. alfalfa, straw, palm fiber)

Recommended: End-Open Corrugated or Inclined (Helical) Corrugated

Why: Both offer strong grip through deep or angled grooves.

Open Corrugated: Great for feeding tough fibers and reducing blockage.

Helical Corrugated: Better flow direction, higher efficiency — good for large biomass lines.

Note: Both types create more friction — expect higher wear and power usage.

3. Sticky or Moist Materials (e.g. wet feed, grass, molasses-added formulas)

Recommended: Corrugated + Dimpled

Why: Combines the grip of grooves and the anti-slip benefit of dimples — ideal for slippery materials.

Bonus: Helps reduce roller slippage and ensures more stable feeding.

Caution: Not as effective with extremely fibrous raw materials.

4. Aquatic and Poultry Feed (smooth, low-fiber formulas)

Recommended: End-Closed Corrugated

Why: Closed- ends prevent leakage, increase extrusion pressure, and ensure even pellet length.

Best For: Side-discharge dies, where clean ends and uniform pellets are key.

Reminder: Clean regularly to avoid material build-up at the ends.

5. Hard, Dense Materials (e.g. wood chips, rice husk)

Recommended: Curved Corrugated

Why: Curved grooves apply steady pressure, reducing breakage and keeping pellet density uniform.

Best For: Long-running lines with stable high-load production.

Not Ideal For: Sticky or fine materials — might cause buildup.

6. Multipurpose or Mixed Materials (e.g. feed, wood, pharma)

Recommended: Fish Bone Corrugated

Why: A versatile option that handles a variety of materials with decent grip.

Note: Performance may drop slightly with high-fiber materials.

✅ Summary Table

| Material Type | Recommended Roller Shell Type(s) |

| Medium-fiber feed | Dimpled (Honeycomb) |

| High-fiber / coarse materials | End-Open or Inclined Corrugated |

| Sticky / wet materials | Corrugated + Dimpled |

| Aquatic & poultry feed | End-Closed Corrugated |

| Hard, dense biomass | Curved Corrugated |

| Mixed / multipurpose materials | Fish Bone Corrugated |

Final Tip from My Side:

When we choose roller shells, we always start by looking at three things:

1. Material type

2. Moisture content

3. Pellet size

Is Choosing the Roller Shell Type Enough?

Choosing the right type is a good first step — but it’s not enough.

Even within the same type, design details matter:

– 🐟 Aquatic feed: Fine-tooth grooves for gentle pressure and uniform pellets.

– 🐓 Livestock feed: Medium-tooth rollers balance grip and smoothness.

– 🌾 Biomass: Wide-tooth rollers handle tough fibers better.

– Dimpled rollers: Small vs. large dimples change grip and friction.

What I Check After Choosing the Type:

– Tooth size or groove width

– Dimple diameter and spacing

– Groove angle and depth (especially for helical/curved types)

These small factors help fine-tune performance, improve pellet quality, reduce slippage, and extend the life of your die and rollers.

Want to Go Deeper?

At Hayne, we have a full technical chart that outlines the design options for each roller shell type — including groove styles, dimple sizes, and more.

Would you like a copy?

Feel free to contact us anytime — we’re here to support your pelleting process with the right solutions.